Mainly engaged in ASU cryogenic air separation, PSA nitrogen generators, PSA oxygen generators, suction dryers, refrigeration dryers, boosters, small liquid nitrogen machines and various supporting air separation equipment.

Purity 97~99.9999%

flow rate 5~50,000Nm3/h

Purity 93%~99.9%

Flow rate 3~15,000Nm3/h

Purity 99.999%

Flow rate 3~3,000Nm3/h

The company has over 20 years of experience in the air separation industry and operates a modern factory of over 30,000 square meters in Hangzhou, China. We have departments for R&D, procurement, production (PSA, air separation, small-scale liquid nitrogen, and valve workshops), and quality management to deliver high-quality products.

With over 20 years of experience in sales projects, understands industry-specific solutions.

24-hour online service support to provide you with answers to various gas problems.

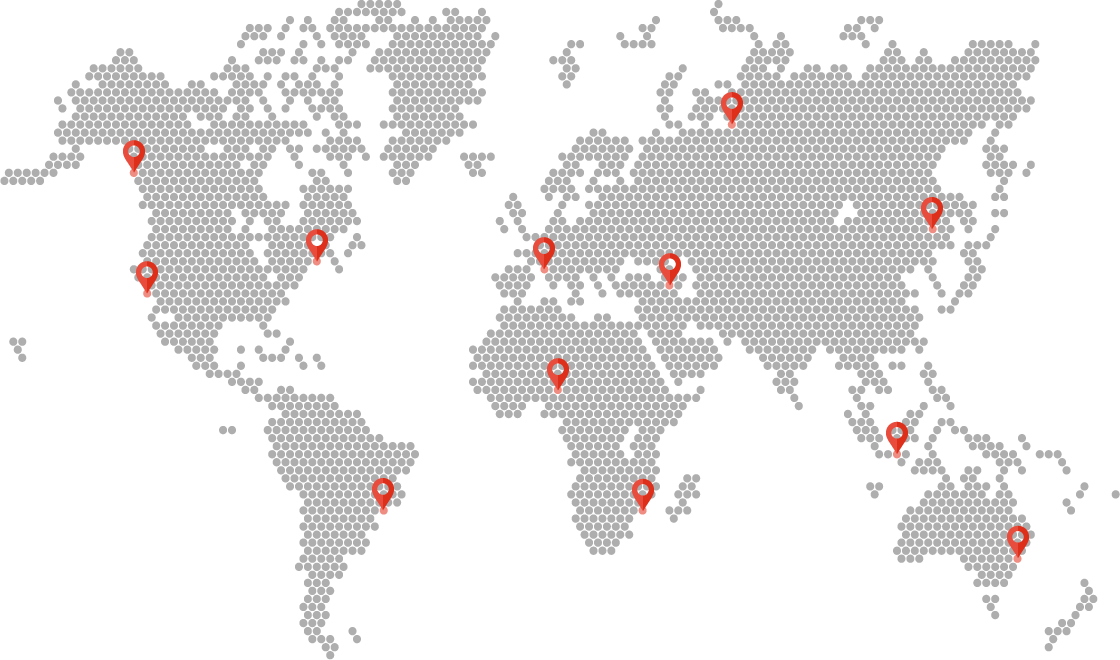

Participated in large-scale international air separation equipment projects

Has over 300 cryogenic air separation projects and pressure swing adsorption (PSA) projects.

Has nearly 60,000 square meters of production facilities with an annual production value of 1 billion.

Separation is achieved using pressure swing adsorption (PSA) due to the different sizes of nitrogen and oxygen molecules.

Gas separation is achieved through cryogenic processes due to the different boiling points of nitrogen, oxygen, and argon.

Separation is achieved using pressure swing adsorption (PSA) due to the different sizes of nitrogen and oxygen molecules.

It has a production base of 30,000 square meters, which can meet the production conditions for an annual output value of 1 billion.

Strictly implement ISO9001 standards

Continuously improve the safety factor of equipment and have various explosion-proof levels

Quam adipiscing habitant lacinia odio proin class quisque in lectus nostra nibh

We continuously improve equipment power consumption, reduce energy usage and reduce carbon emissions

Our products are used in various industries

In future industrial development, seizing opportunities for engineering innovation is key to success. By optimizing air separation technology and advancing R&D and smart manufacturing, companies can achieve outstanding industrial results and lay a solid foundation for future growth

The products are used in industries such as manufacturing, healthcare, food and beverage, plastic production, cable industry, laser cutting, and heat treatment.

Common customer questions—see if any of these address your needs.

Pressure abnormalities are one of the common issues with air separation equipment. During operation, the system pressure may experience abnormal fluctuations, typically caused by compressor faults, pipeline leaks or blockages, or pressure sensor malfunctions. To address this issue, it is necessary to:

Cooling system failures can lead to unstable temperature control, affecting the efficiency and purity of gas separation. This may be caused by poor cooling water circulation, ice formation or blockages in the cooler, or malfunctioning temperature sensors. To address this issue, it is necessary to:

This includes issues such as damaged packing or trays in the separation column, improper setting of operating parameters, and high impurity content in the feed gas. To address these issues:

Excessive energy consumption may be caused by equipment aging or reduced efficiency, suboptimal operating parameters, or system leaks. To address this issue:

Common causes of control system failures include software or hardware malfunctions, faulty sensors or actuators, and loose or faulty electrical connections. To address these issues:

If you have any questions or would like to book a session please contact us.